Welcome to Mechanitron Corp

Quality Precise Reliable Machining Services

About Mechanitron

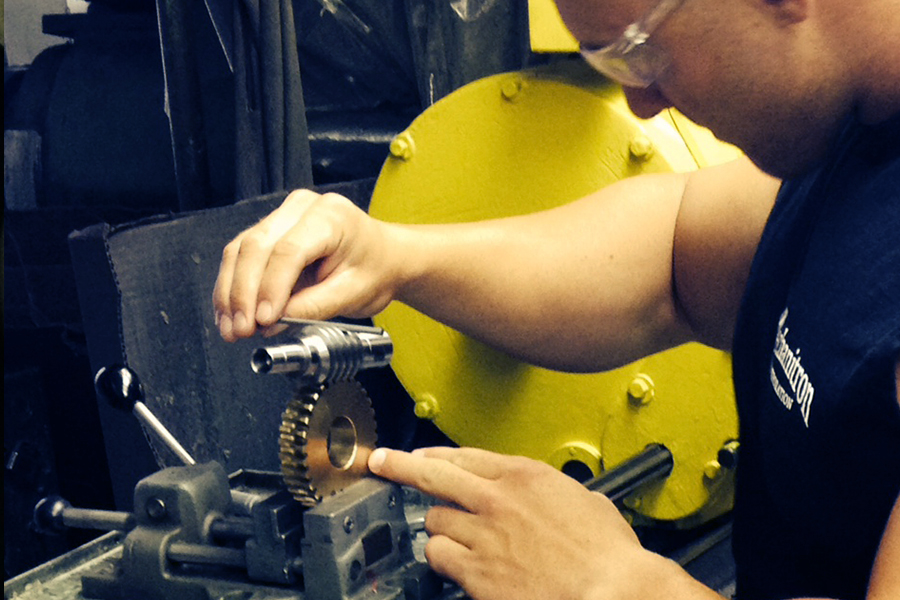

Mechanitron specializes in the design and manufacture of high precision metal components. While the majority of business in the past had been to provide highly specialized components for military and aerospace applications. In recent years the corporation has expanded the business to include commercial, medical and pharmaceutical components. The work we do is highly specialized and we have been at for over 50 years. Leading companies in their fields like DuPont, Westinghouse, Marconi of Canada, General Electric, Becton Dickenson and others who deal in components and products as varied as aircraft, optics, communications, surgical etc., know they can count on us for work requiring the utmost skill and precision done properly and delivered on time.

We can put a thread so fine (100 p) it is barely visible to the naked eye or screw diameter of a sewing needle, or thread apiece of steel a full grown man cannot lift.

Industries

Motion

Manufacturing motion thru actuation devices, multi-start worms , cam and shaft systems and transmission components.

Aerospace

Machining of positioning screws for interior and exterior on aircraft systems. Clients include: Triumph Aerospace Systems, Marathonnorco Aerospace Systems.

Military

We manufacture parts for some of this countries leading defense contractors providing launching screws, and missile, explosive and helicopter components.

Surgical

Serving the medical industry is a privilege. We manufacture bone screws and surgical taps that are made from the toughest unmachinable materials that need to be ground; Titanium & Tungsten.

Our Clients Say